Water Injection

Injection of water into an internal combustion engine has been around for 50+ years.

It has been used effectively in the Formula 1 motor sport in the 70 ties and 80 ties, before it was banded, for adding too much power to the turbo charged engines.

Advantages

- The introduction of water will allow higher boost pressures to be run without detonation. Higher pressures will increase torque

- Water Injection allows ignition timing to be more aggressive

- Boost does not automatically mean retard your timing

- The cooling of potential hot spots in the combustion chamber defeats pre-ignition, the most destructive form of uncontrolled or unplanned combustion

- Water injection has a cooling effect on the engine head, valves, and cylinder

- Excessive amounts of ignition retard will cause a loss of power and overheating

- Water does not burn. There will be no combustion of the hydrogen in the H2O

- Injection of 15% water reduces knock better than increasing fuel 4-5 Octane

- Injection of water reduces inlet air temperature equal more power

The picture shows cylinder pressure versus crank angle traces at different operating conditions

- Green curve: Normal timing condition

- Yellow curve: 3 deg before normal ‘slight knock’ engine limit

- Red curve: 6 deg before normal ‘intense knock’ can produce permanent engine damage

- Blue curve: 6 deg before normal but adding water

Before TDC, the blue trace followed a predictable path except soon after the TDC, the pressure begins to flatten. As the water within the combustion chamber started to evaporate and absorbed a large amount of the heat and prevented the pressure and temperature reaching the point of detonation. The trace now follows the green trace until the next cycle. Note the area under the blue trace is much larger than the green trace indicating torque increase. More gains are to be expected on the turbocharged engine.

What to do or not

- Water or Water / Alcohol to Fuel Ratios should be between 10% to 25%

- Water Injection could be up to 50/50 water alcohol (or methanol) mixture

- Water to Fuel ratios should be based on weight and not volume

- Air to Fluid Ratios is between 11.1:1 and 10.0:1 with water injection

- Maximum Torque occurs at a 13.2:1 Air to Fuel Ratio

- The latent heat of evaporation water is 2256kJ/kg (0.626kW), approximately six times more than gasoline

- Atomization of the water mixture is directly related to it effectiveness. Finer droplets cool the inlet charge better

- Maximum water delivery should be at maximum torque RPM tapering somewhat at maximum RPM

- Inject the water spray before the throttle body

- Atomized water (like fuel) does not like to make turns

- Don’t flow water through an intercooler

- Don’t use fuel injectors they will corrode or rust shut in a very short period of time

The Aquamist S-1 Water Injection System

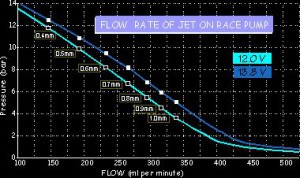

I am using the S1 with a green 0.5mm jet. With the 187ml water/min and a fuel flow at 1.3l/(0.95kg)/min at 250HP/(390nm), the water injection is approx 20%.

The inlet air temperature reduces approx. 6-10 deg. C.

The system is controlled by the ECU and is active from >150kpa and >2500 rpm.

It’s amazing what the Water Injection can do:

Lower inlet temperature. More aggressive timing. Higher torque. Better Knock margin at the same 99 octane fuel. The engine also sounds much softer at high power development.

The ERL Aquamist S1 system: www.aquamist.co.uk

Video: Water Jet ‘green 0.5mm – 187ml/min 11bar’