Wood Pellet Gasifier

Wood Pellet Gasifier

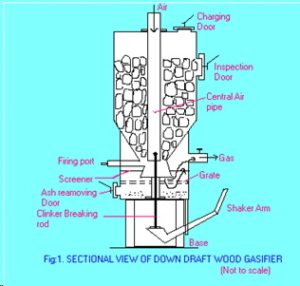

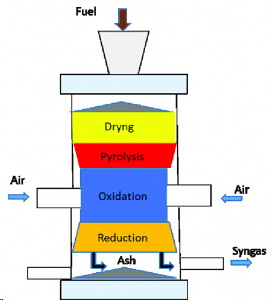

The gas from wood is called Syngas an abbreviation for synthesis gas. Gasification is a process that converts organic or fossil based carbonaceous materials, here wood pellets, into carbon monoxide, hydrogen and carbon dioxide and some more. This is achieved by reacting the material at high temperatures (>700 °C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is called syngas which is itself a fuel. The wood goes through several stages. The picture shows a so-called downdraft gasifier which I was planning to do. This has the advantage that tart and Acetic acid from the wood generated in the pyrolysis area is sucked through the burn area oxidation/reduction and converted into Methane and Carbon monoxide which is burnable.

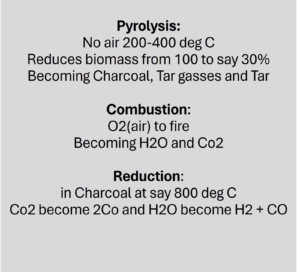

The pellets will be Drying at about 100 deg C The Pyrolysis is the first step in gasification and combustion. It occurs in the absence or near absence of oxygen, and it is thus distinct from combustion (burning), which can take place only if sufficient oxygen is present (charred pellets). he burn is in the Oxidation zone. The rate of pyrolysis increases with temperature. Here about 800 deg C. Reduction is the direct reverse process of combustion. Combustion is the combination of combustible gases with oxygen to release heat, producing water vapor and carbon dioxide as waste products. Reduction is the removal of oxygen from these waste products at high temperature to produce combustible gases (Syngas). Wood pellets will give 3-5kWh per kg. Gasoline is about 9 kwh/liter. Wood gas has about 20% Hydrogen (H) 3 % Methane (CH4), 20% Carbon monoxide (Co) and 55% Nitrogen (N2) and some Carbon Dioxide (Co2) and Tart