SU HIF6 Dual Needle Tracker Wintek SDNT 500

The SU Carburetor is a very smart construction.

SU’s works on the principle that fuel is let into the engine in response to the level of suction in the inlet manifold. This pulls up the piston pulling the tapered fuel needle out of a hole (the main jet) containing a petrol feed, the more suction the bigger the effective hole to spill petrol into the inlet manifold. The amount of petrol entering the engine is then a function of the suction (aka size of fuel hole) and the amount of airflow. The airflow is a function of engine speed and throttle opening.

To counteract this piston lift, a large soft spring has a light press on top of the piston. This is usual a yellow version strength. Don’t change that but change the fuel needle curvature.

The piston works as a variable venturi. At low rpm and load the piston is only a little open and speed up the airflow to give a better air fill in the engine and better low-end torque. At high rpm and load, the piston is full open and let a lot of air and fuel going into the engine.

In single SU configuration there is only two screws to be adjusted. Idle rpm and idle mixture. At say 800 RPM turn the mixture screw to AFR 12.8-13. (Screw in then richer)

In a dual SU configuration, the two cabs must be balanced.

Set a fastish idle speed (1200rpm) and use the idle adjustment screws to get the same amount of air going down each carb. With the air cleaner off just use a piece of old heater hose to listen to the airflow into each carb – a bit like a doctor’s stethoscope – and get the wheezing the same.

Try to set the mixture screws at the same staring point and repeat the process iterative for best idle at say 800 RPM.

The tuning of the SU’s to match the engine is done via changing the tapered fuel needle. Hundreds of different shapes had been available early days. Today much fewer is available.

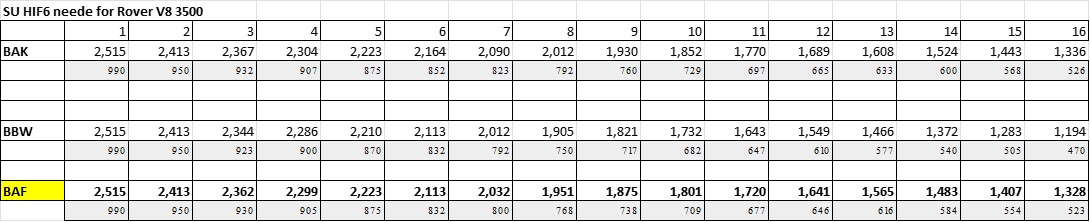

The needle is specified in 16 zones

The needle is specified in 16 zones

With the engine off the SU is fully closed needle at station 1 (only a little of depending of the idle point).

Idle is approx. 1-3. Cruise 3-7. Top speed 8-11. There is 3.15 mm between each station.

In the 3500 V8 with two SU HIF6 the needles could be BAK, BBW or BAF needles, sometime also others.

Belove is diameter of the BAK, BBW and a BAF needles at stations 1 to 16.

For fun and as only few different needs are available, I decide to develop a tool that could measure the needle station during engine run and still have the air-filter installed.

It should indicate the needle station, the air fuel mixture, AFR and the RPM.

With that information I can, during a dyno run, log, and see if the needle profile matches the desired AFR at a given RPM and load.

I had several ideas. One where the piston height changes an LC circuit resonance frequency. That took 40 mm above the SU and the bonnet could not be closed with the system installed.

I ended up with developing a system measuring the distance inside the Damper down to the piston tube using infra read light reflections. I painted the top of the tube with reflecting silver paint.

As an IR system will have an output log to distance, I developed an anti-log amplifier to have a liner station reading. It also should be temperature compensate to be stable over a 10-70 deg C.

I developed a stable system and tried to make my own needle profile to match the engine. I started out with the BAK needle and ended up with a profile that almost matches the BAF needle.

To change of ‘1’ AFR in a specific needle station using 400 sandpaper 5 mm wide and a light press on the desired station in 5 seconds at needle rotation of 2000 rpm.