Engine theory

Car Power Source

The car engine is a machine that converts fuel energy to a rotating motion commonly measured in horsepower. In the engine gasoline is added to air through carburettors or fuel injectors on its way to the cylinder. The mixture is burned in the cylinder creating heat which creates pressure and turns the crank shaft.

Fuel chemical energy

One pound gasoline contains 19,000-20,000 Btu (British thermal unit). The energy of one horse power (1 HP) is 2,545 Btu per hour.

A theoretical engine with 100% efficiency will burn: 4,242 Btu/min/100Hp= 0,135l/min/100HP

1 litre fuel typically weighs = 726g

Thermal efficiency (TE)

Getting more fuel/air into the cylinder means more fuel energy is available to make power.

Things that will affect the thermal efficiency of an engine are: Compression ratio, ignition timing, thermal isolation, plug location, chamber and cam design.

A low compression street engine will have a total TE of approx. 0.26 (26%)

The street engine will then burn approx 0.5 litre/min/100 HP

A race engine can achieve up to more than a TE of 0.34 (34%)

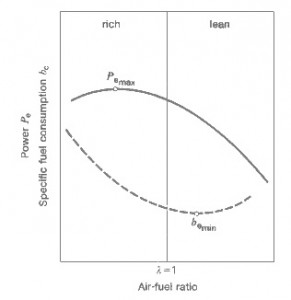

Mixture

The nominal ratio of air to fuel is 14.7kg air to 1kg fuel. A typical engine should run a little richer at idle, a little leaner at mid RPM and a little richer at full RPM.

Max power will occur at A/F 12.2:1

Min fuel consumption at A/F 16.2:1

Volumetric Efficiency (VE)

Volumetric Efficiency is defined as how much air is really sucked into the cylinder on the intake stroke compared to the cylinder volume.

A cylinder will have some restricted intake, such as a small carburettor and loss in the intake filter and pipes.

A typical Natural Aspirated (N.A.) engine will have a VE around 80-100%. Maximum at maximum torque.

Let’s take at 1600cc four stroke engine and a VE of 95%

Each cylinder will suck 0.95×0.4= 0.38 litre air per two RPM

Temperature

Air has different weight at different temperature and air pressure. More air/oxygen will burn more fuel. The cooler the air the more oxygen per m3.

At 101.3 kpa or 1013mb the air will weigh the following at different temperatures:

1275g /m3 at 0 deg C

1168g/m3 at 25 deg C

1078g/m3 at 50 deg C

This shows that increasing the inlet temperature from 25deg C to 50deg C will reduce the air mass with 7,7% and then ultimately reduce the power with 7,7%.

Mechanical Efficiency

Depending of how much fuel gets into the cylinder, depending on the VE, and how much of the fuel gets converted to workable power, some of this power is used by the engine to run itself. The left over power is what you can measure on the dynamometer. The difference between what you would measure on the dyno and the workable power in the cylinder is the mechanical efficiency (ME).

Mechanical efficiency is effected by rocker friction, bearing friction, piston skirt area and all other moving parts, but also the engine RPM. The higher the RPM, the more power it takes to turn the engine.

ME is often expressed in terms of friction horsepower.

Engine maths example

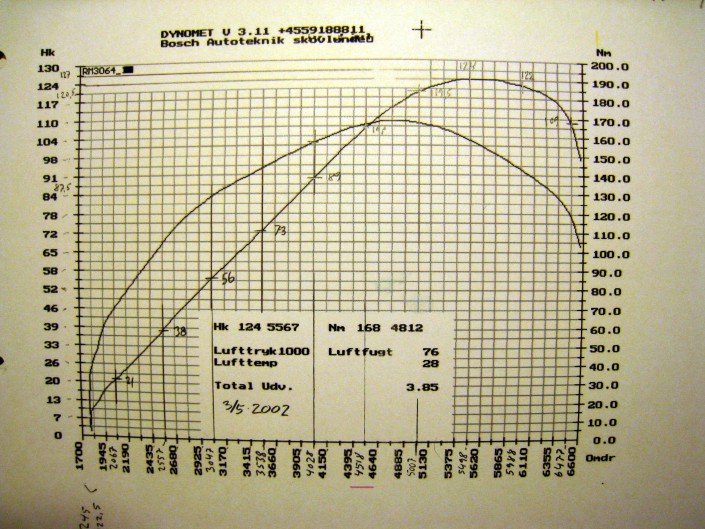

Lets take a 4 strokes 4 cylinder 1600cc N.A. engine at 25 deg C, air pressure 101,3 kpa and a VE of 0.95.

Let’s run it at max power 6000 RPM and A/F 12.2:1

It will take 6000/2×1.6×0.95 l/min= 4,56 litre air/min

Air weight at 25 deg C = 1168g/m3

The engine will then suck 1169gx4,56= 5.330g air/min

At 6.000 RPM and max power you have to add (A/F 12.2:1) 5.330/12.2 g fuel /min= 437g fuel/min = 437/726 litre/min = 0.602 litre fuel/min

With 0.5 litre fuel/min/100 HP the engine should produce…

The 1600cc Engine at 6000 RPM should produce = 100×0.602/0.5= 120 HP

Power (kW) = Power (HP) x 0.7457= 120×0.7457= 89.48kW

Power (HP) = Power (kW) x 1.341

THIS IS ALMOST WHAT THE DYNO PLOT SHOWS

The dyno plot is from a slightly tuned engine